Printing Puppets.

Printing Puppets is a research thesis completed as part of a Masters of Design Innovation at the Victoria University of Wellington, under the supervision of Ross Stevens.

This research reimagines a 120-year-old animation process using the most advanced forms of digital manufacturing technology.

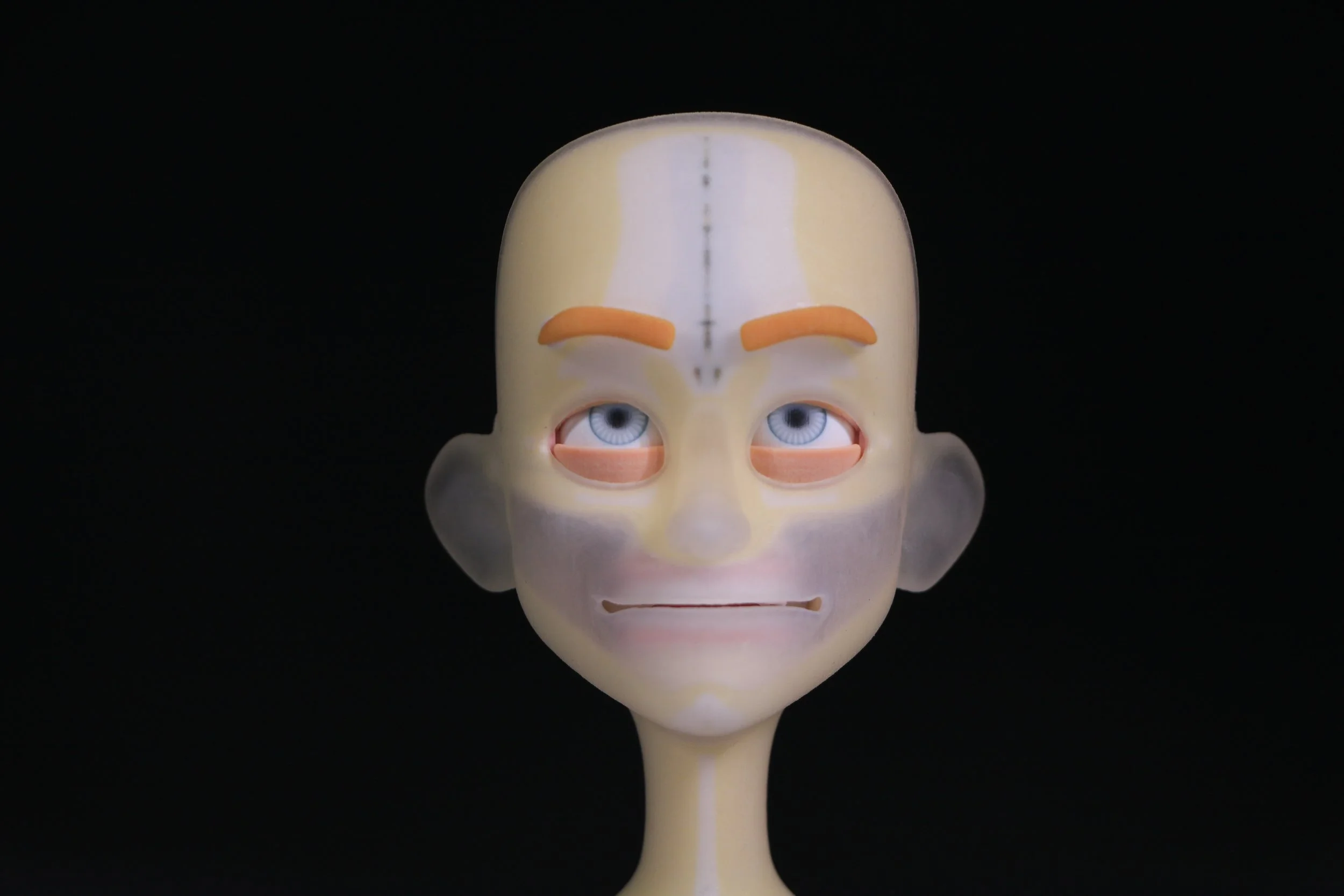

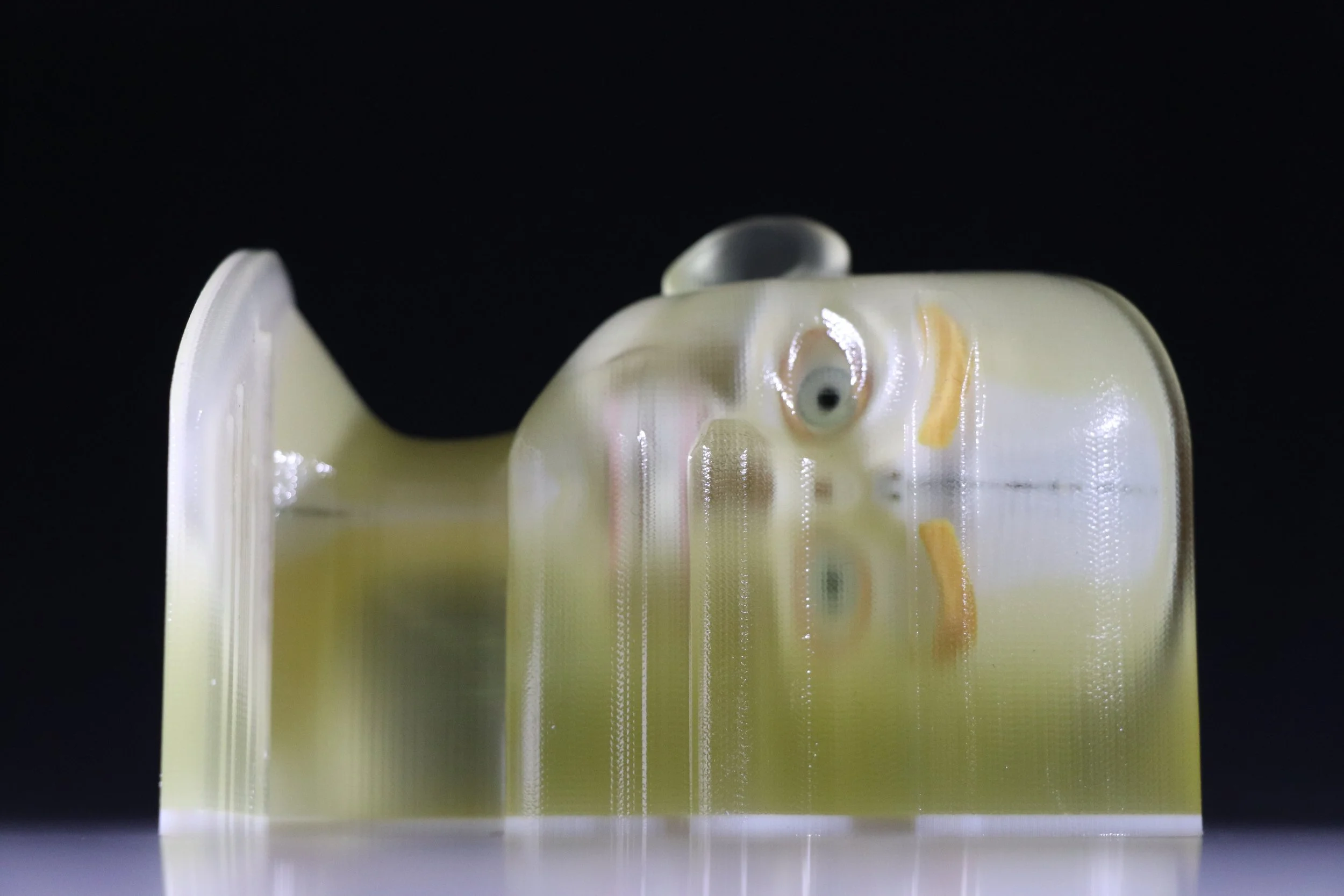

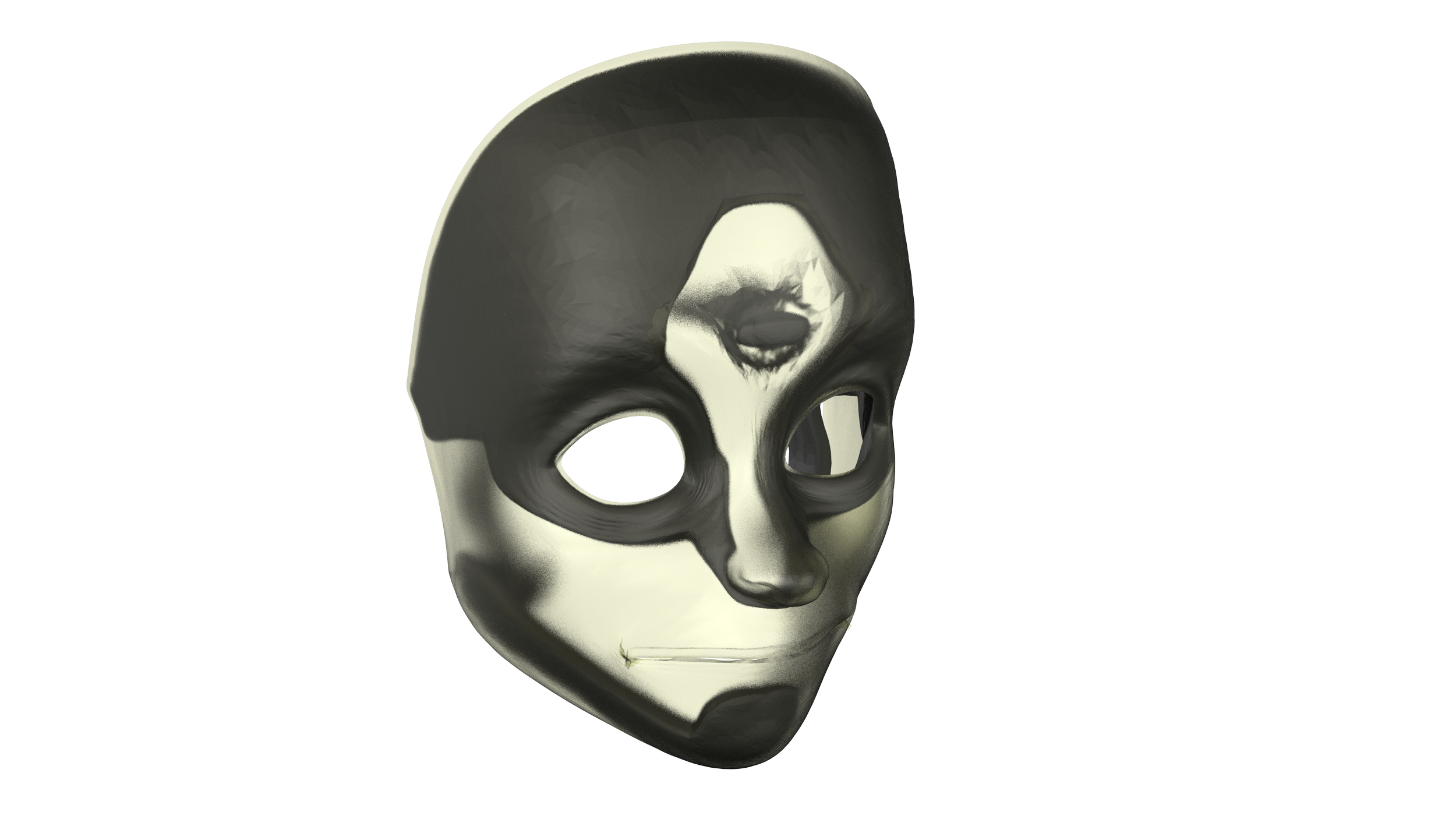

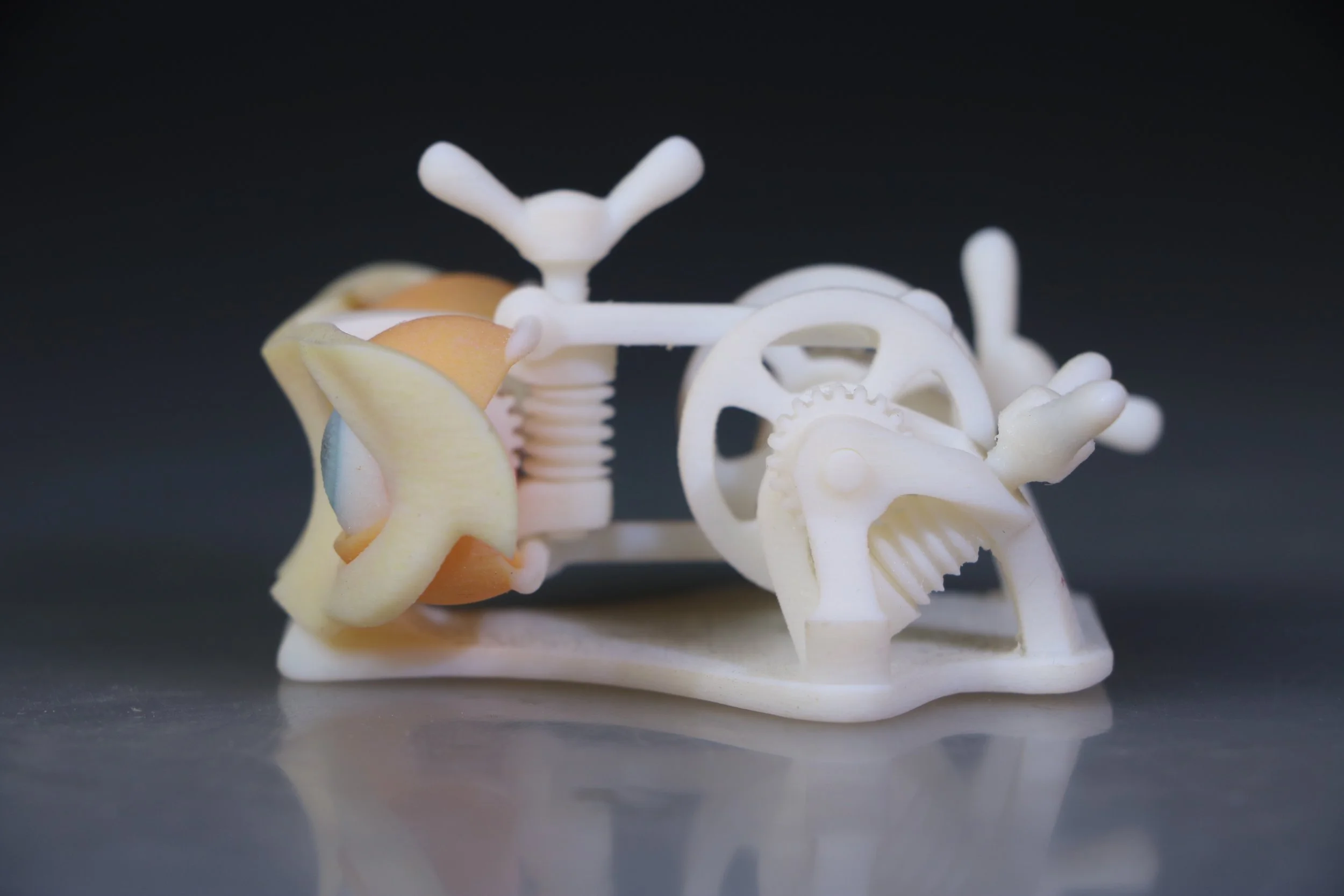

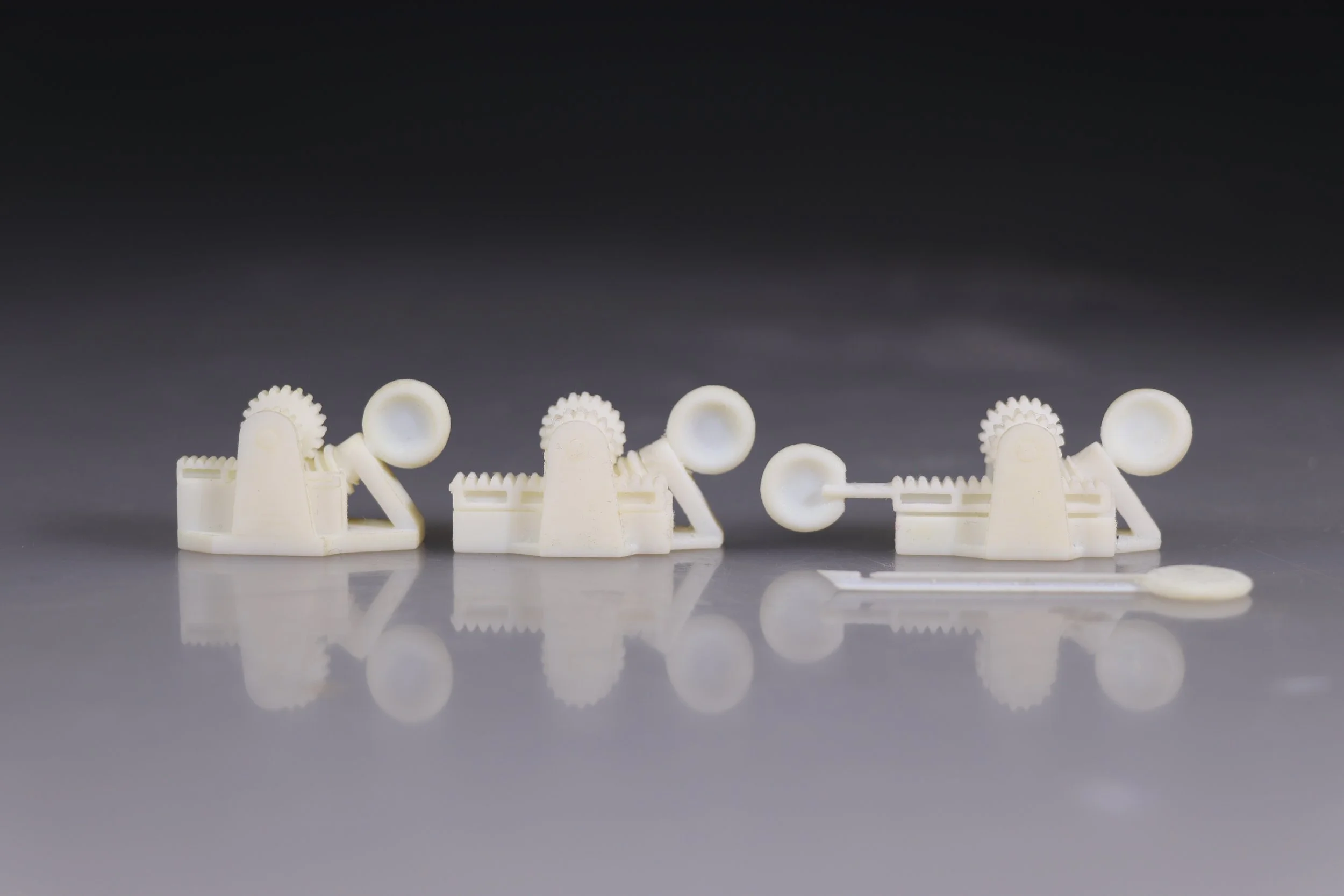

Using the Stratasys J850’s accuracy and Multi-Material capabilities this research is aimed to push the boundaries of the latest 3D printing technology and see if these advances can simplify the complex design and manufacture involved in an artform as demanding as Stop-Motion animation.

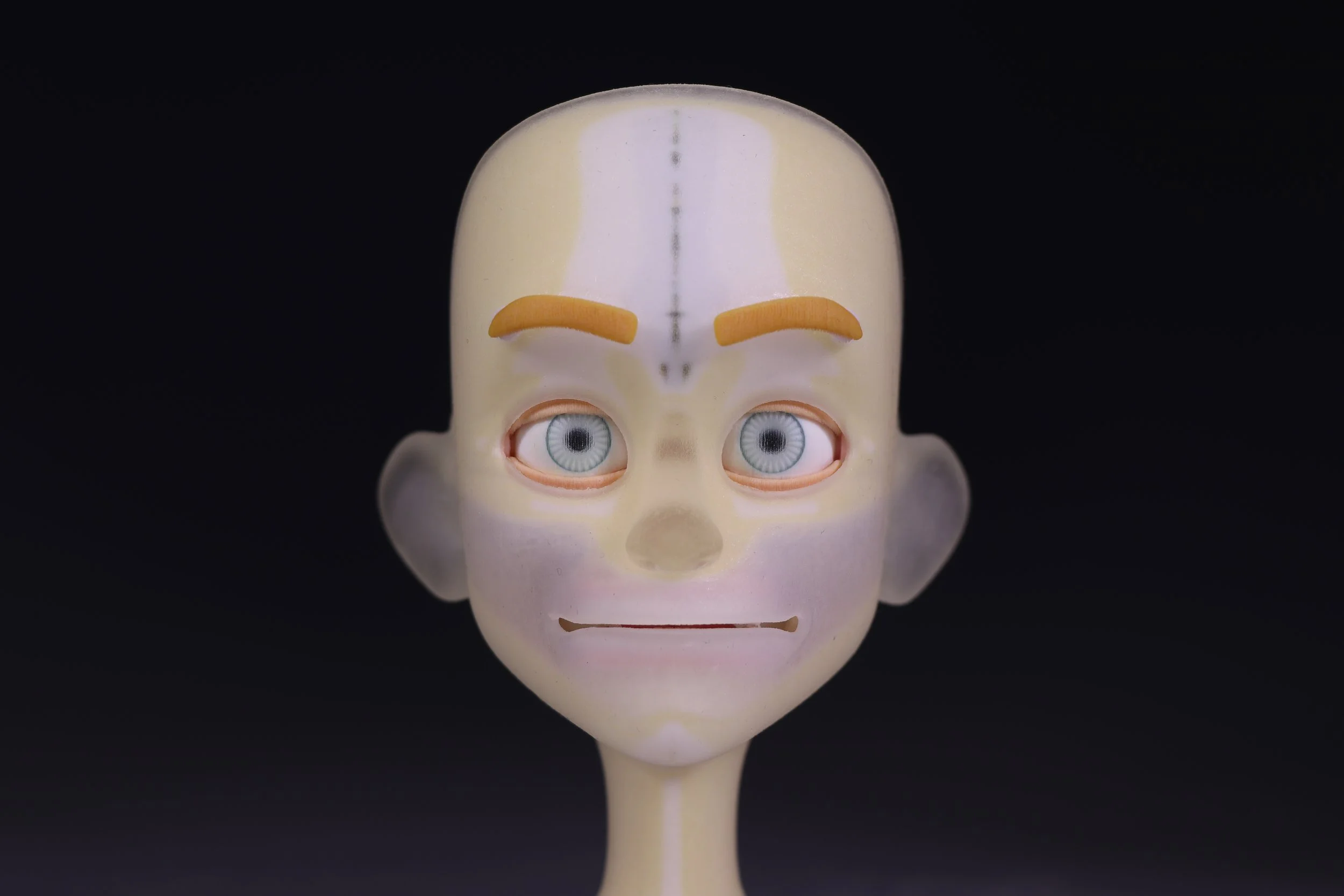

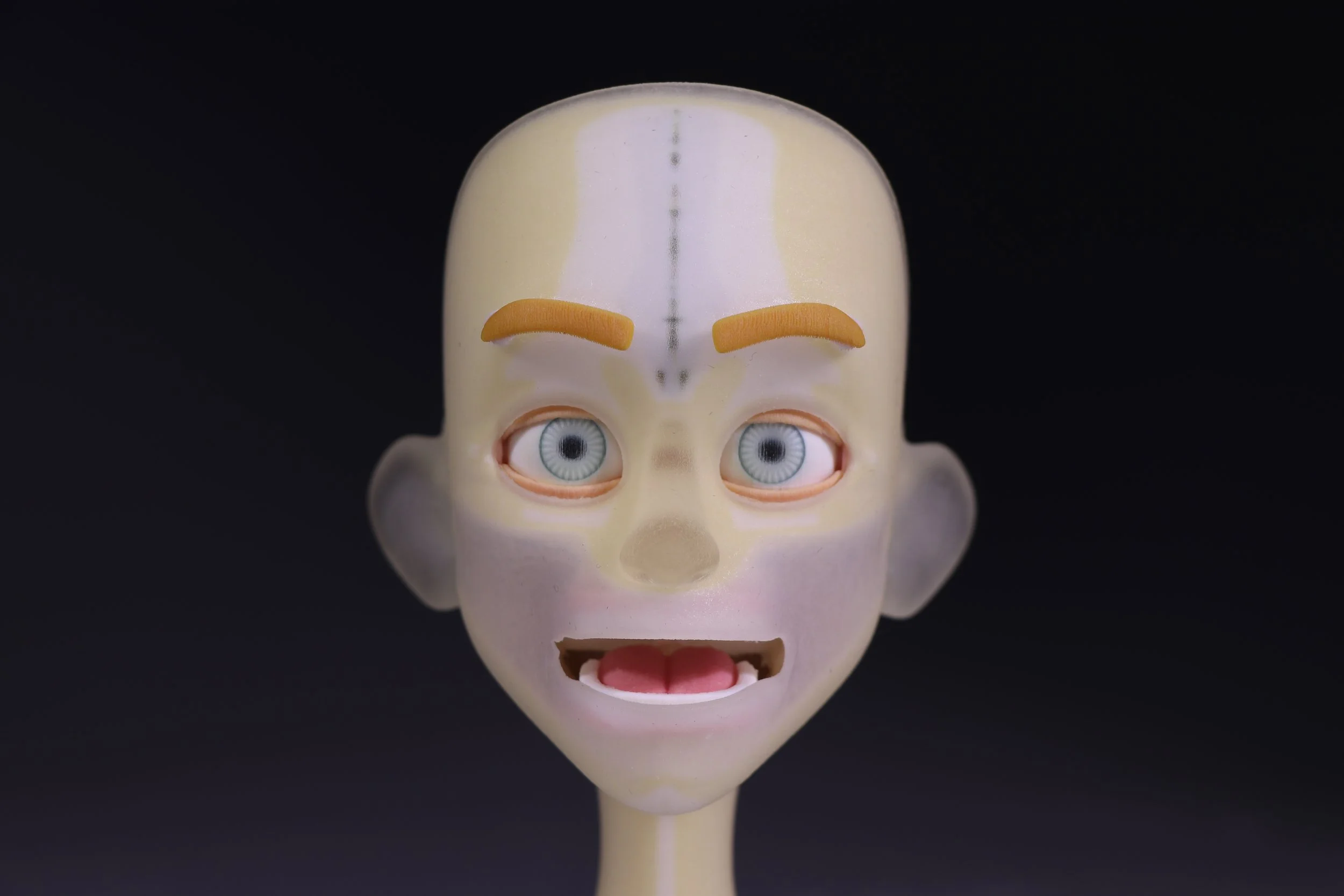

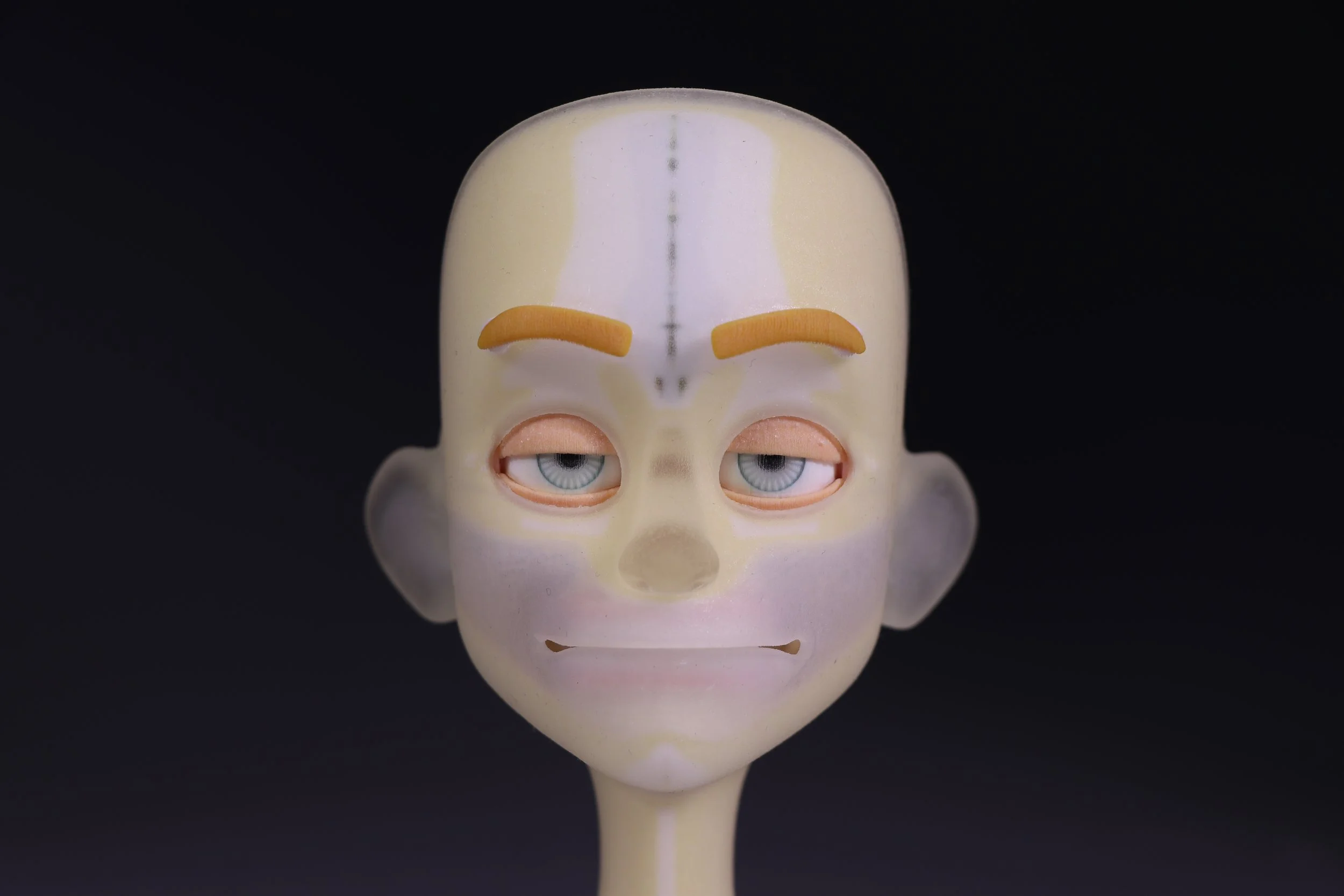

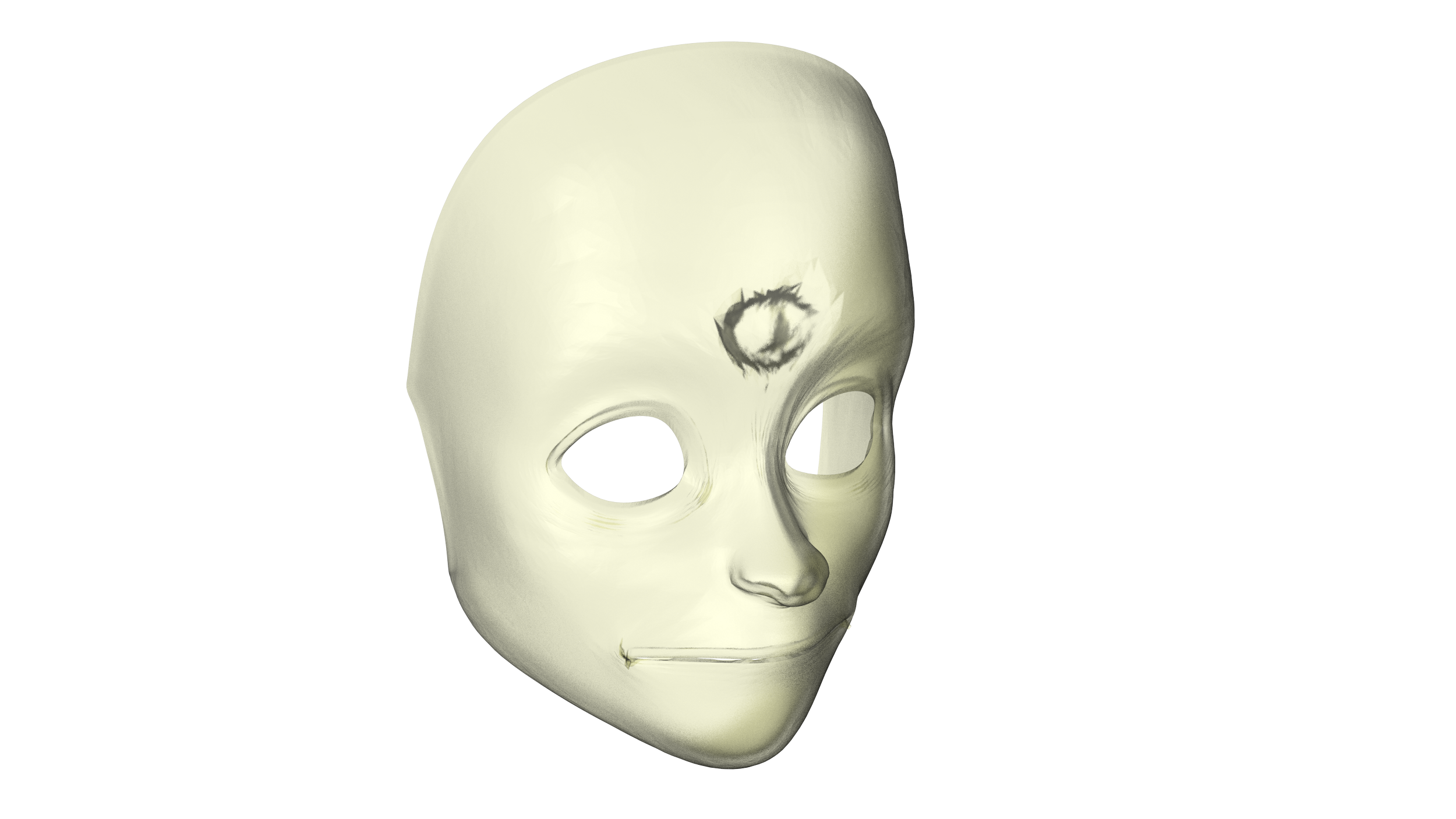

Can something as complex as a mechanically posed Stop-Motion animation puppet head, with variable colour, and part density (flexible face) be 3D printed in a single file without any form of assembly? … Can a single 3D print be brought to life?

Combination of influence.

Inspiration was drawn from two award-winning Stop-Motion animation studios and combining their differing methods of facial animation. Mackinnon & Saunders’ work in Tim Burton’s Corpse Bride, and Laika Studios’ work on Missing Link. Using the ease/speed of manufacture exploited by Laika’s Stratasys Polyjet 3D printing advancements without needing to print every frame, and using Mackinnon & Saunder’s use of re-posable mechanics without having to meticulously handcraft each puppet.

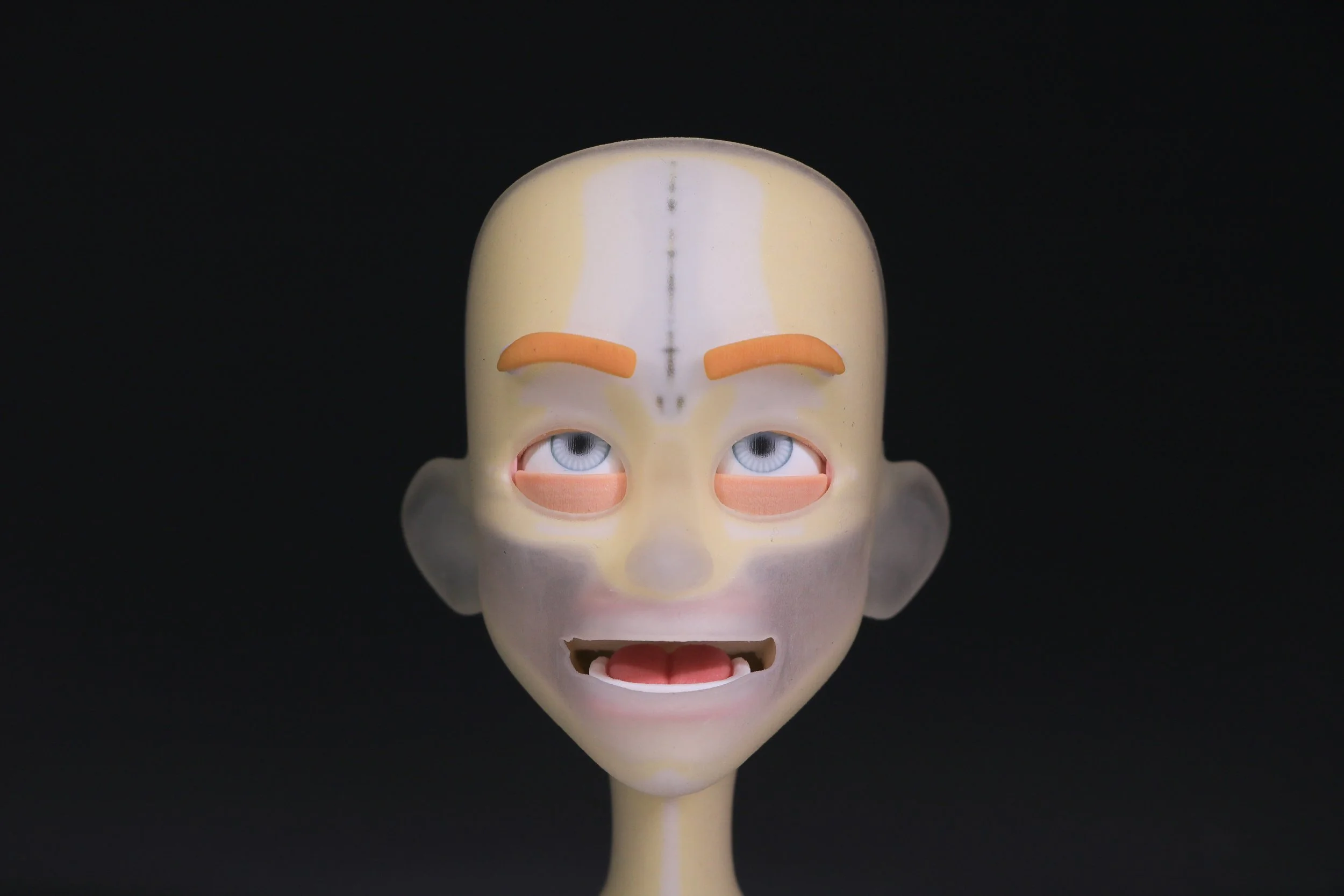

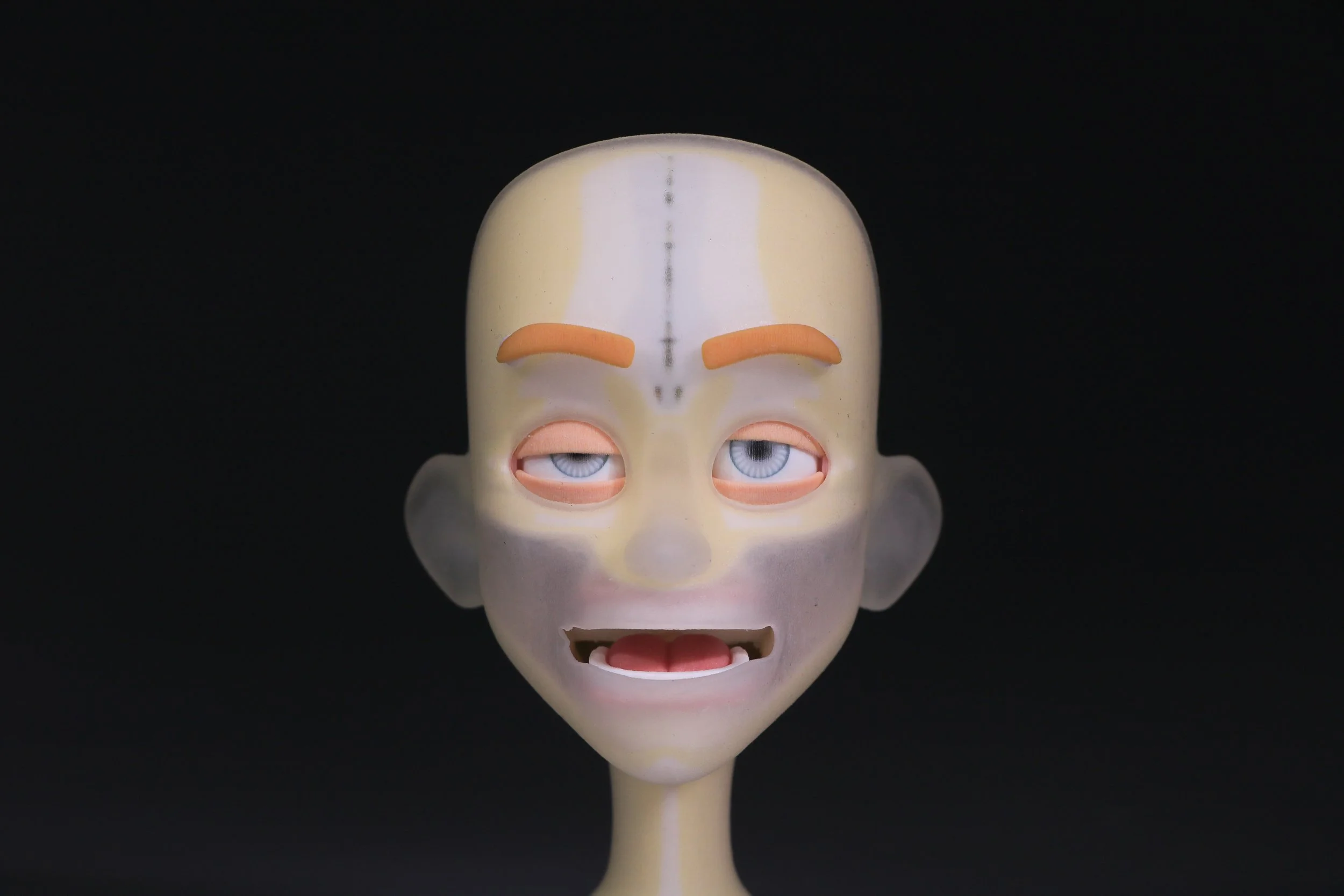

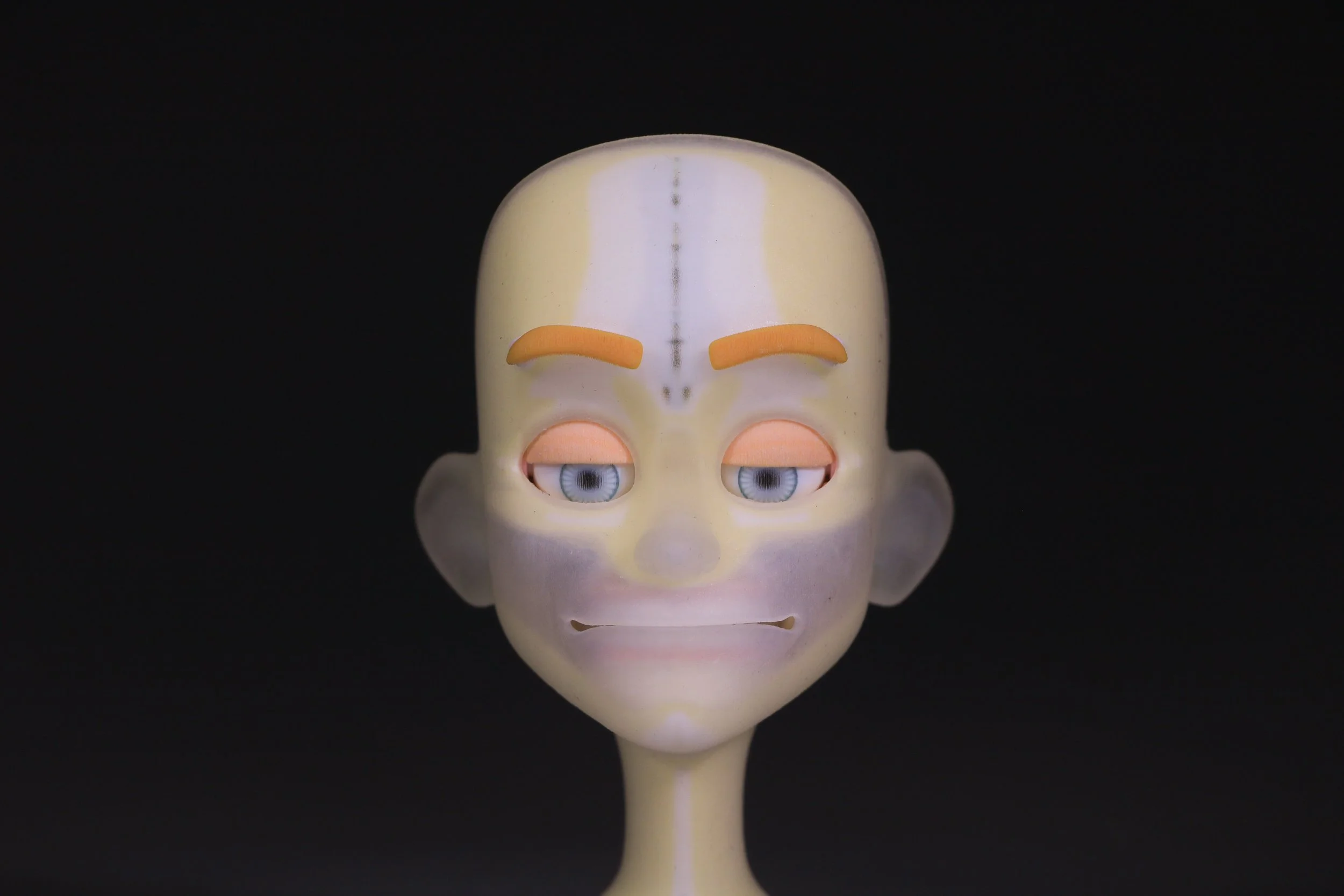

Jeffrey Jr.

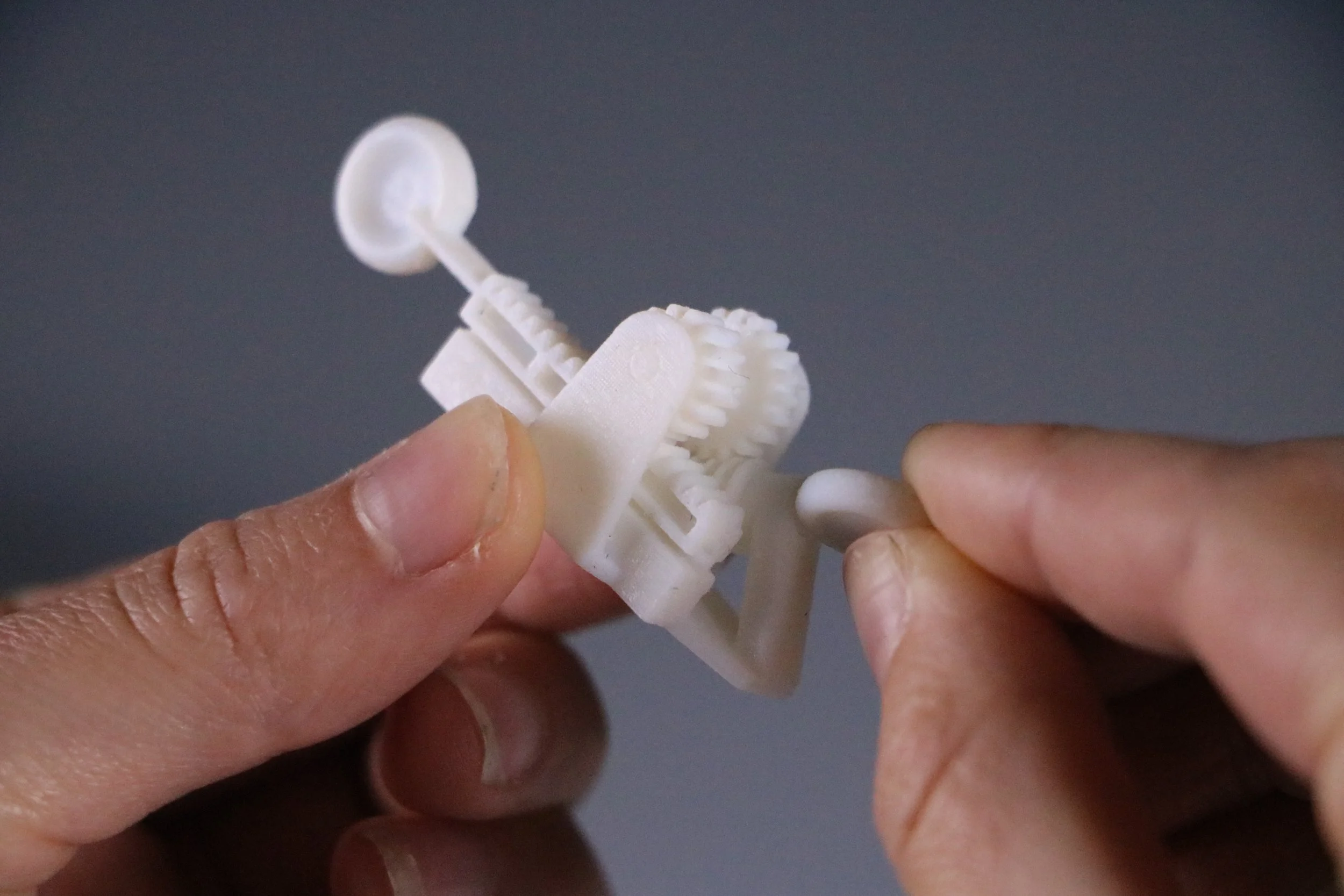

Jeffrey Jr. is Jeffrey Sr.’s younger and less capable counterpart, the first complete assembly printed as one. He is the focus of the submitted thesis, and lessons learned from him resulted in the full functionality of Jeffrey Sr. seen above.

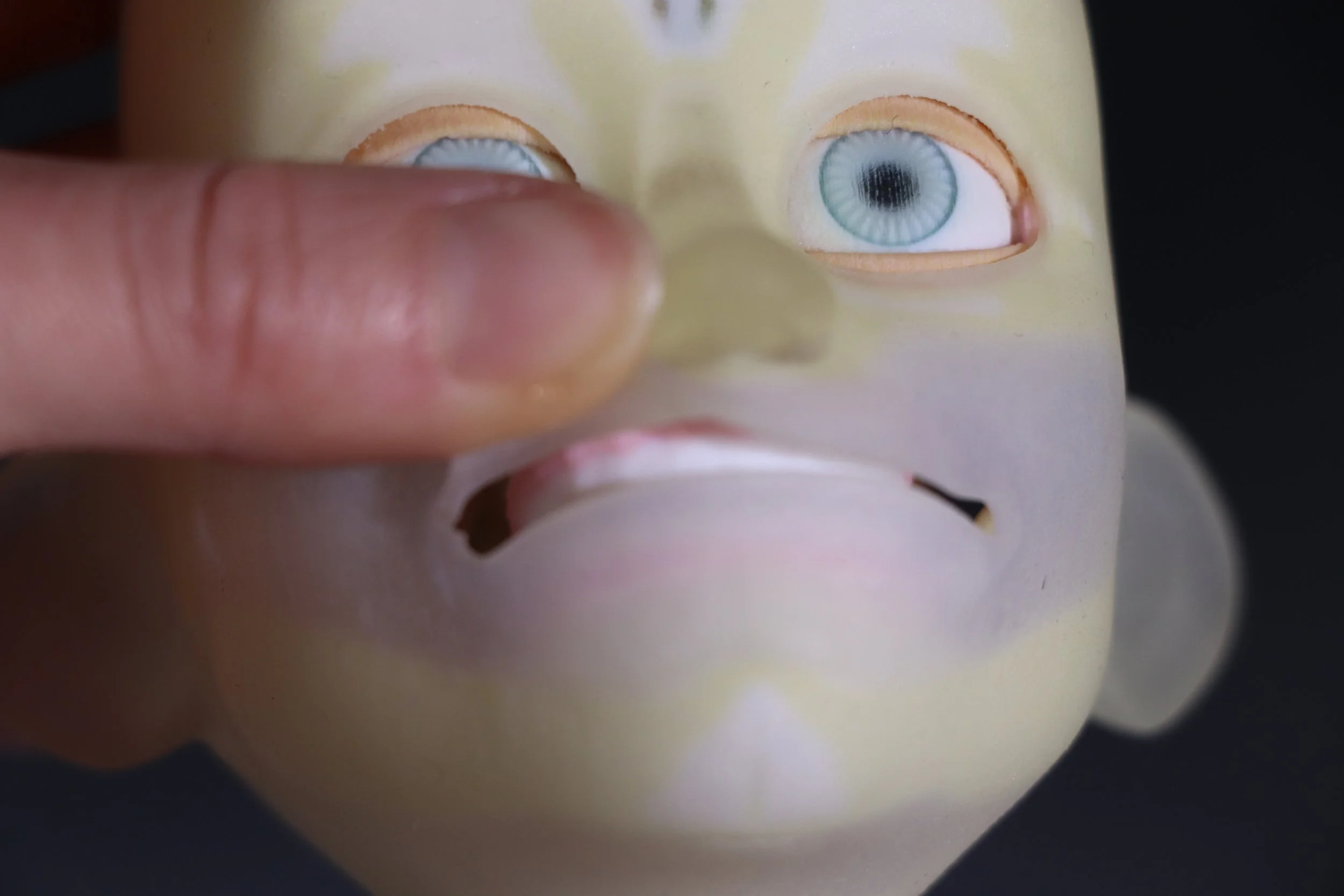

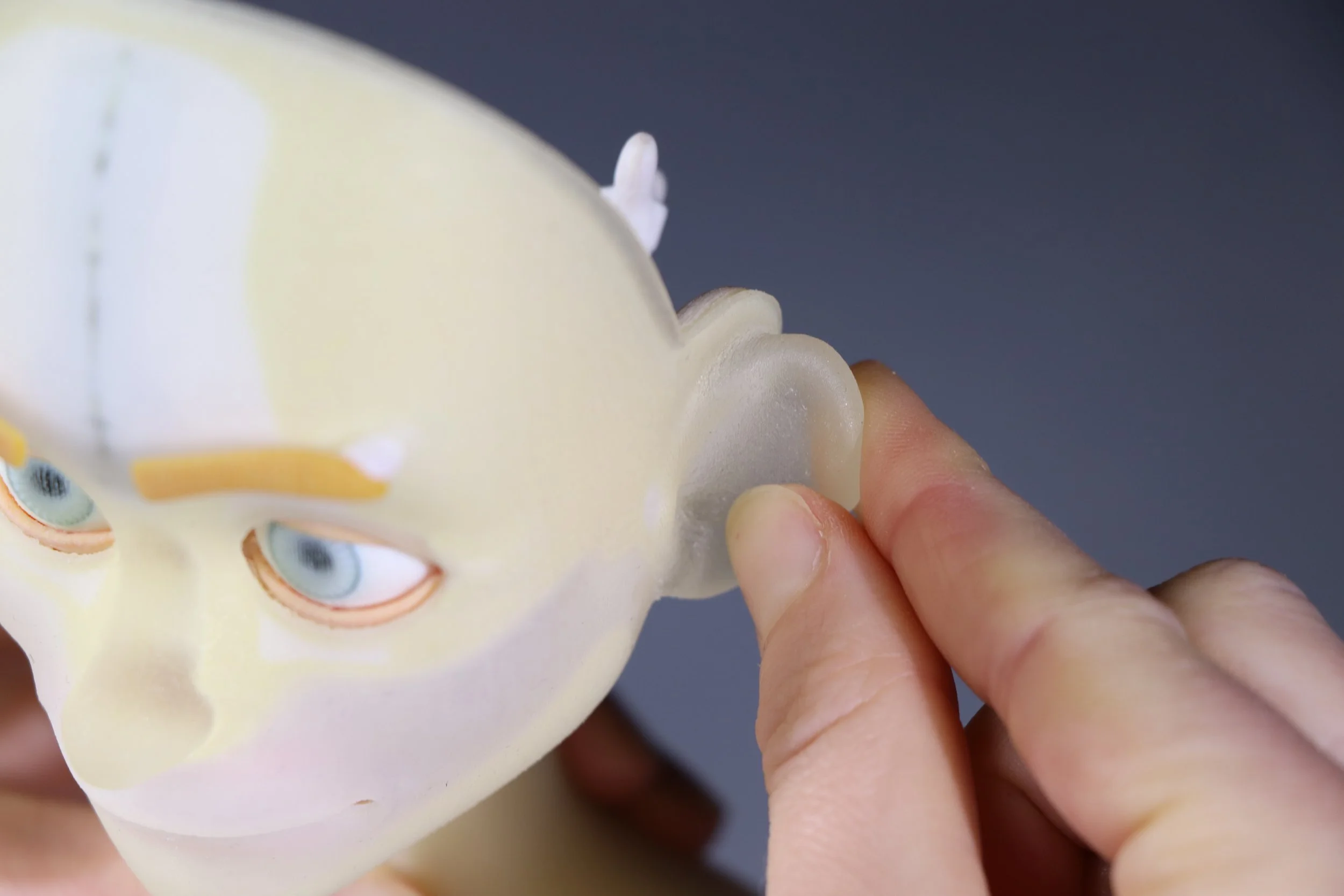

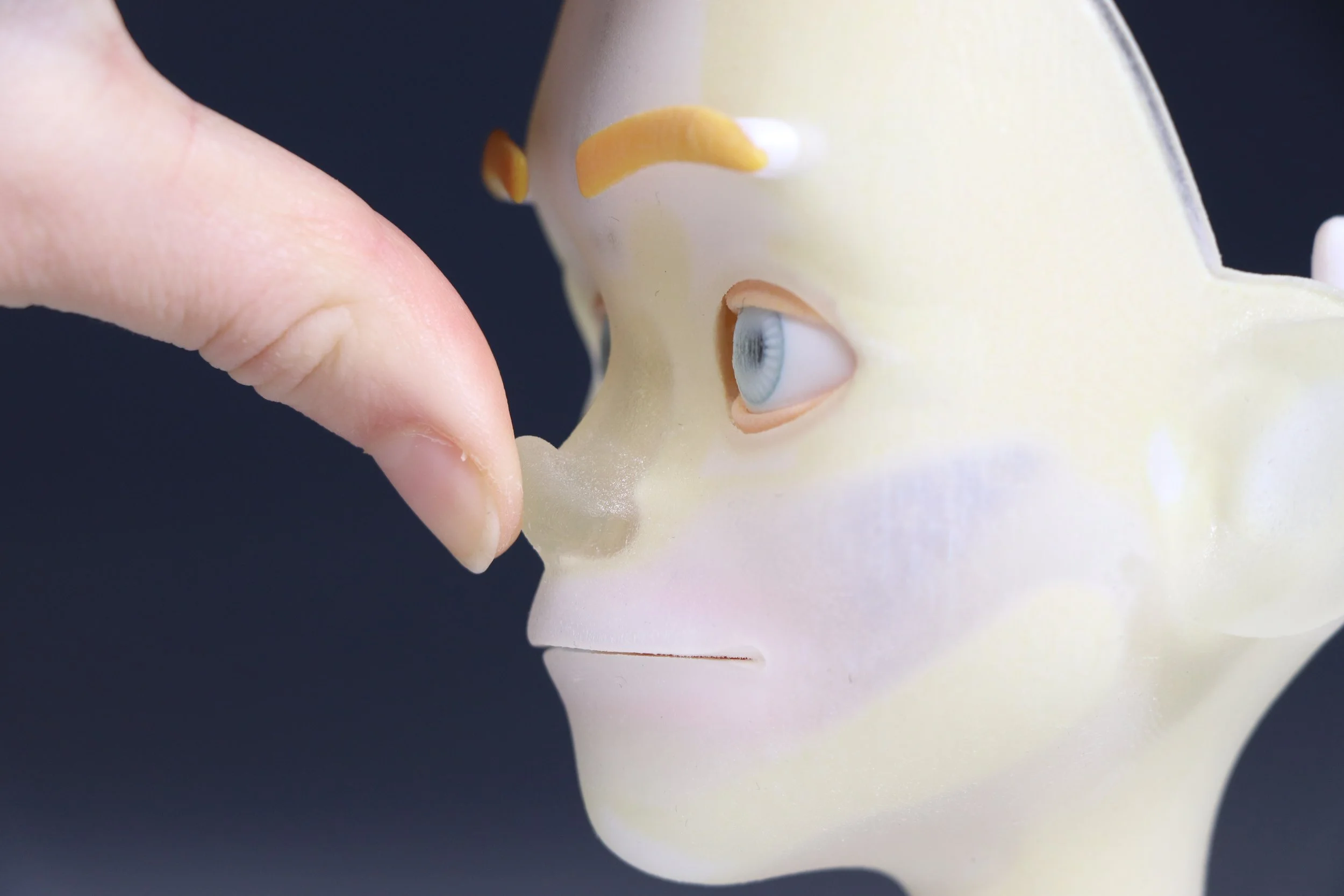

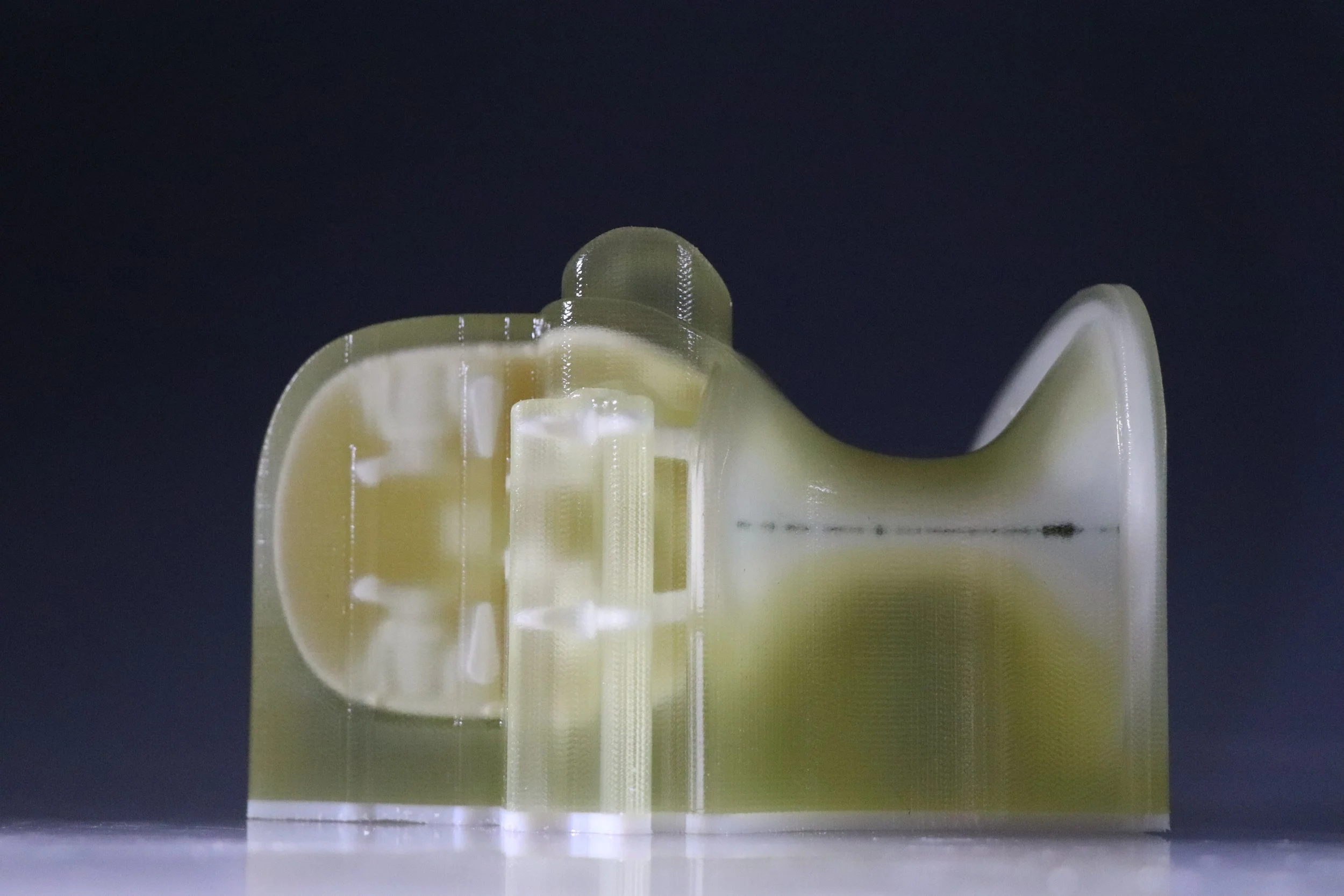

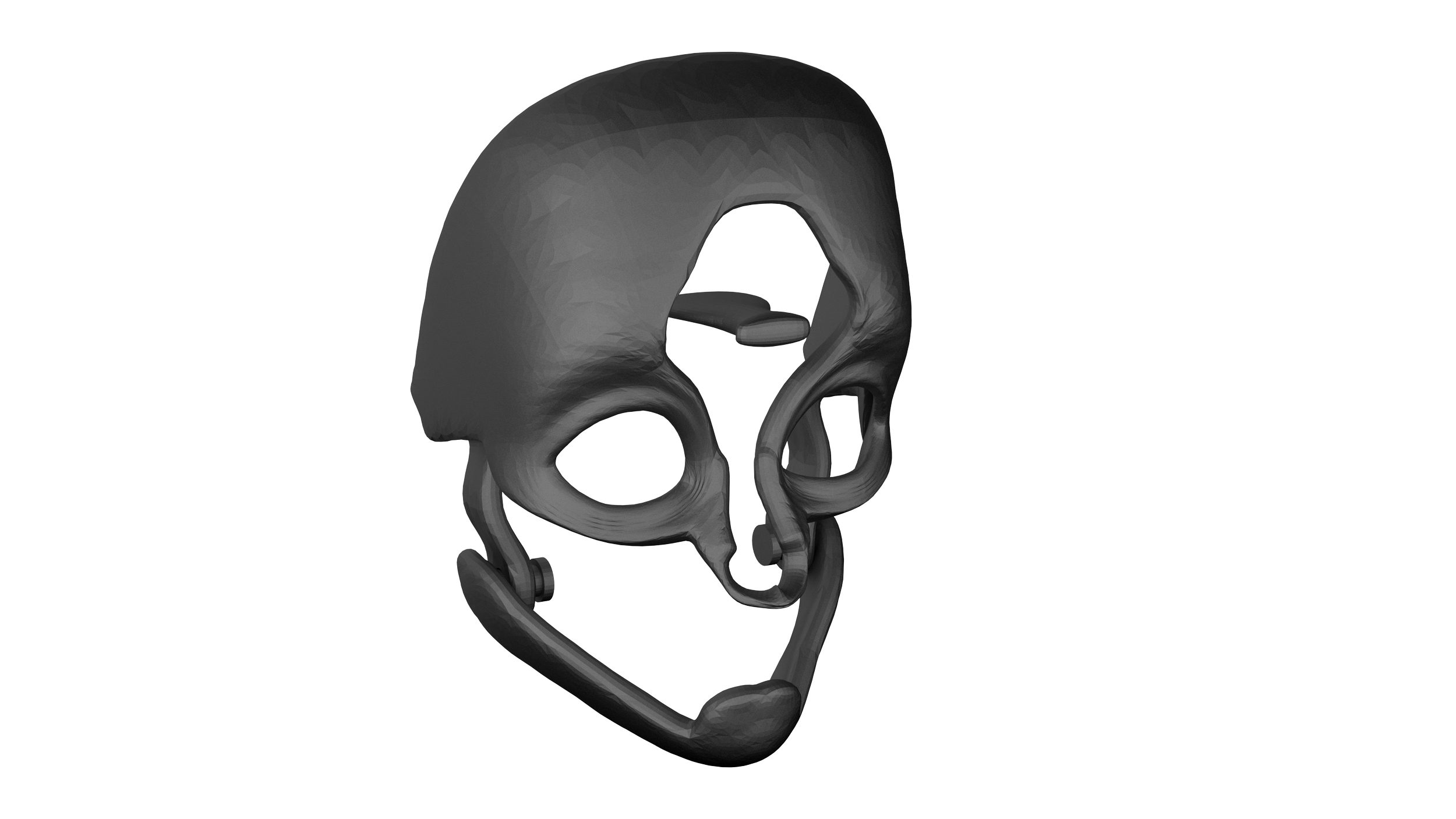

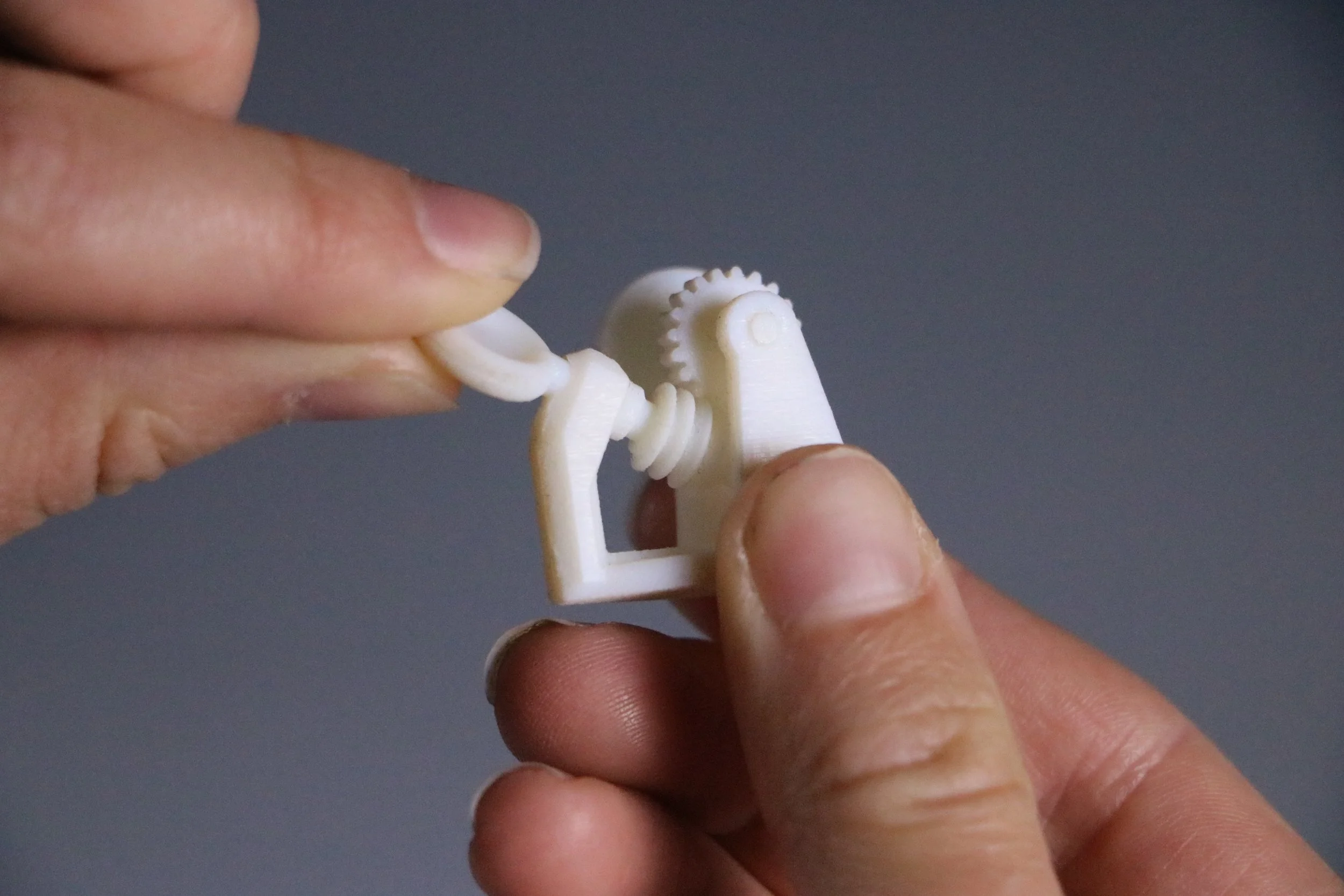

No Assembly Required.

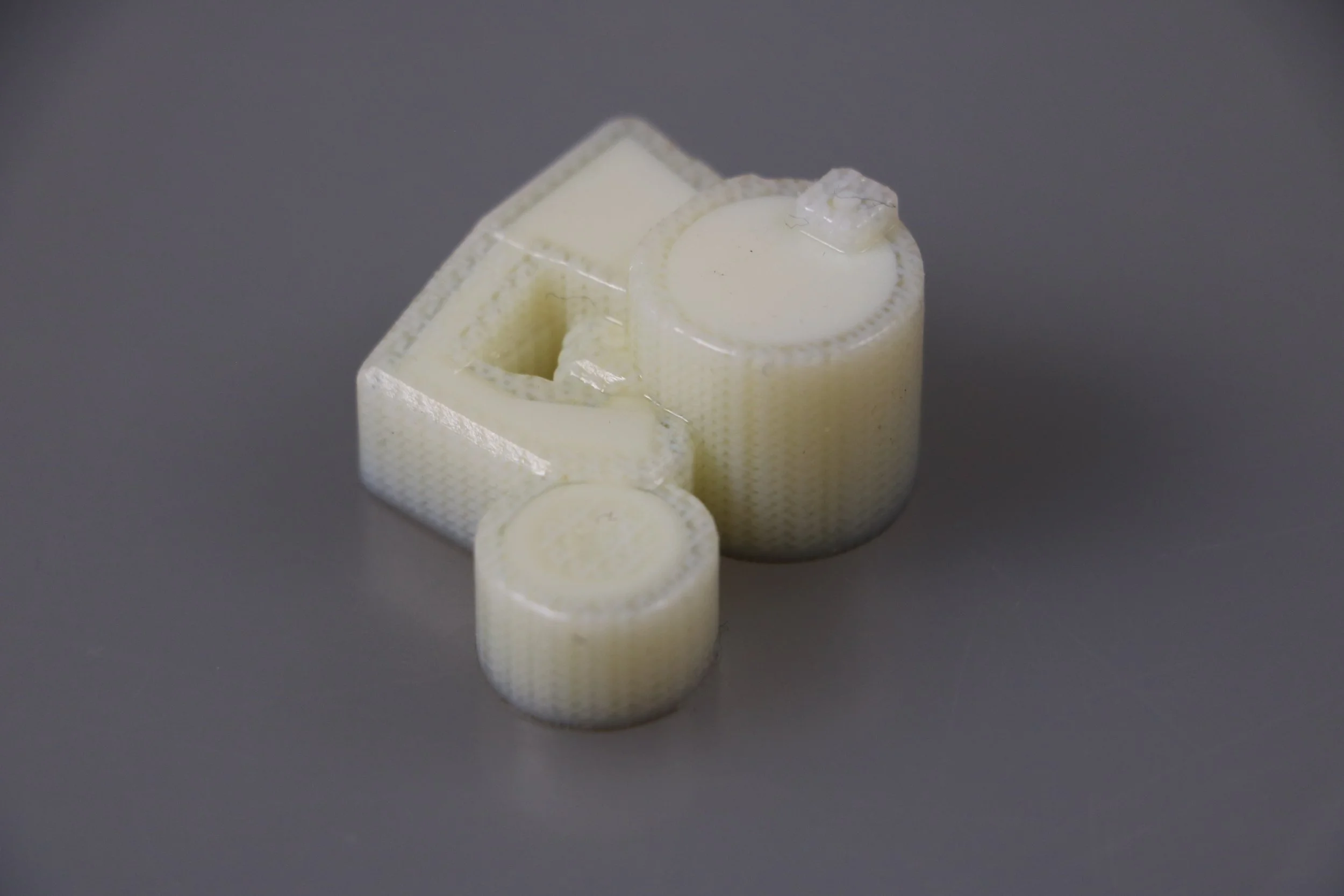

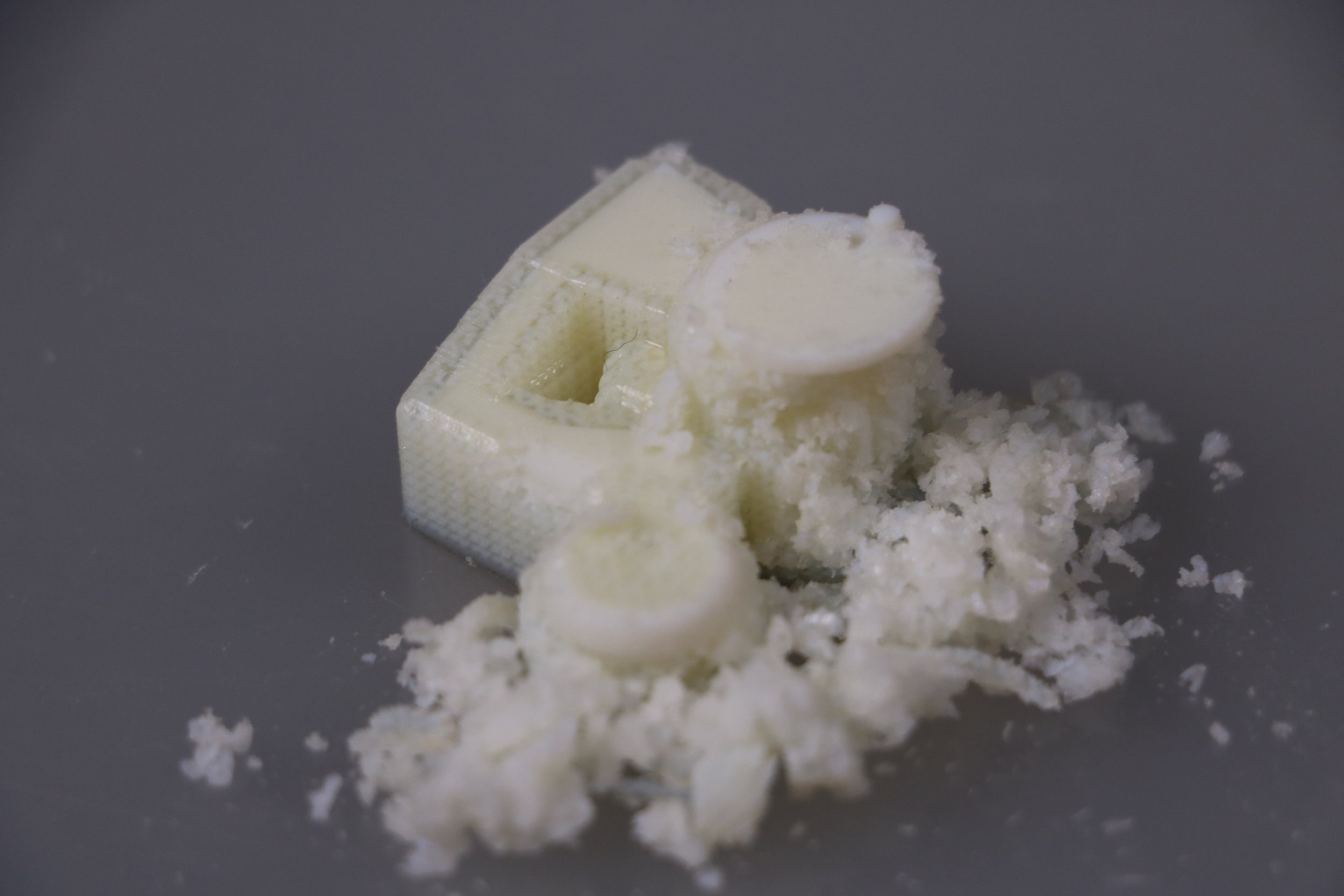

The accuracy of Poly-jet 3D Printing alongside gelatinous crumbling, water-soluble support material allowed me to print intricate preassembled mechanisms. The moving parts freed with hand-cleaning, pressure washing, and the careful application of force. This 3D printing technology allowed the creation of something as complex as Jeffrey to be completely digital, from design to manufacture. This completely transforms the workflows and skills required to bring something like Jeffery from an idea to existence, whether it be in the field of robotics or engineering. And with further development in hardware and materials who knows where this technology could lead to?.